It’s possible to unknowingly experience the effect of the bad pump especially for those with little experience on vehicles. You must have the right knowledge about your vehicle before you know how to tell if the water pump is bad.

It’s possible to unknowingly experience the effect of the bad pump especially for those with little experience on vehicles. You must have the right knowledge about your vehicle before you know how to tell if the water pump is bad.

When you want to replace a water pump for the vehicle, by doing the repair or maintenance, the safety is essential.

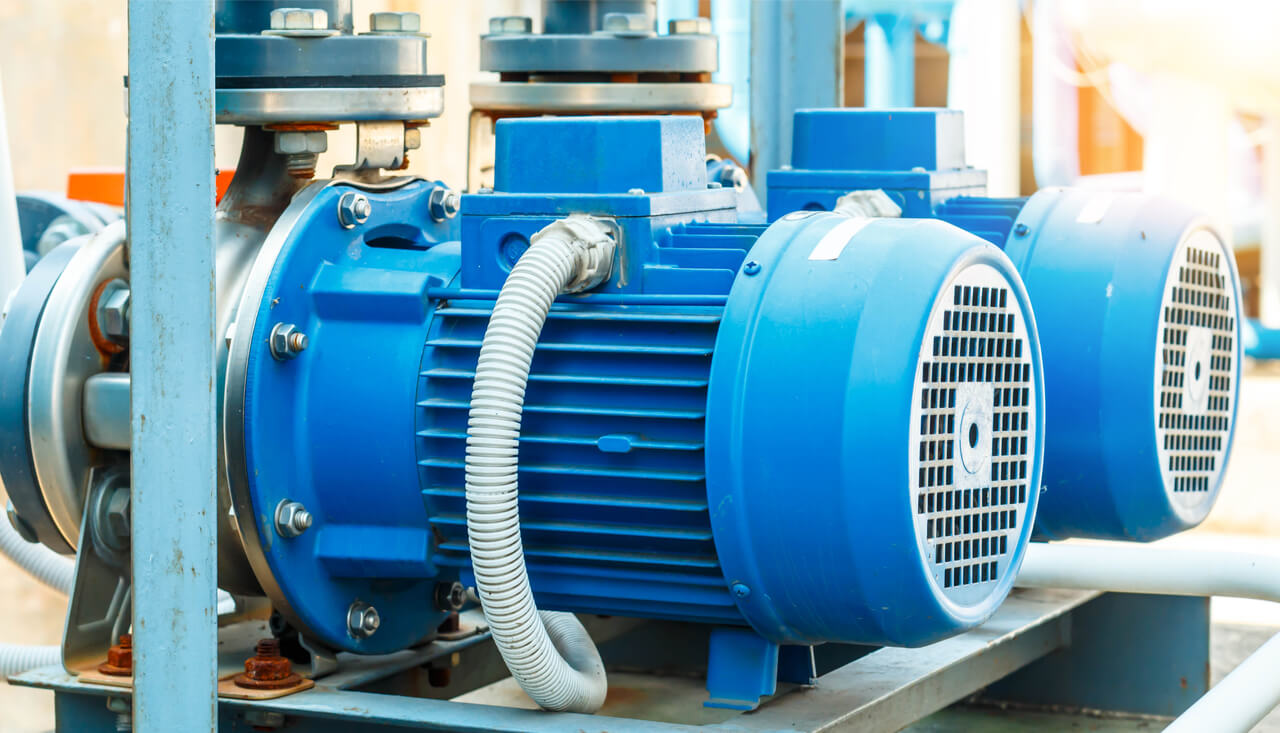

If you have had past experience with a liquid compressor such as water, then it will be easy to have the right understanding of how it works. Most of the water compressors have been designed with the right techniques to control water pressure. To easily achieve the high pressure that is expected from the compressor, volume must be highly reduced.

Most of the water compressors are made of strong materials that are able to withstand the high pressure that is caused. Liquid compressors will save you the hustle of water transportation over a long distance using properly connected pipes. If you’re looking for compressors of any type, there are available compressors online at catanicompresors.com.au.

So you’re seeking a solution on home water pressure pump repair! Perhaps, the pump has jammed. Maybe, some parts of the pump aren’t working. Regardless of the reason, fixing the problem early is always advisable. Failure to do so can result in the total damage of the pump. When this happens, you won’t be able […]

Owning a home requires a water pump around your basement to pump water to any location you wish. Water pumps can also drain out runoff water seeping around your basement to another suitable location such as your garden. This avoids damage that runoff water is likely to cause to your basements. It is very crucial […]

Technology is quickly changing with almost every aspect of life receiving changes. Unlike in the past where most of the home operation were manual, the automatic water pump for home has created a lot of changes. The market now enjoys different supplies for automatic water pump which is more beneficial to the users. Whether you […]